Creating the pathway from design to manufacture

Linking engineering, purchasing and aftermarket requirements to NPI, injection moulding production and engineered assemblies.

Who We Are

We are an award-winning and leading provider of injection moulded parts and engineered assemblies for the most demanding of applications, supporting product whole life from tool design and manufacture, through to production requirements and aftermarket demand. Our business model creates a true partnership where both supplier and customer are fully integrated, relying on each other to successfully deliver results to the end customer.

Seamless integration between design, procurement, engineering and production

What We Do.

Reach out to our team

If you want supply chain excellence and a range of value add services, reach out to our team by email or by phone, and tell us what you need.

Discovery

Understanding the project, identifying opportunity and risk, planning timelines, and discussing outcomes with a collaborative approach aligned with the customer’s needs.

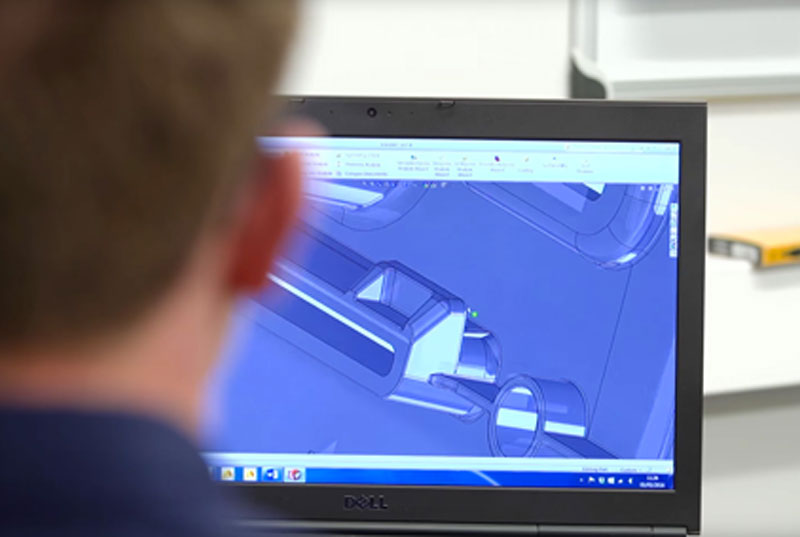

Design for Manufacture

The key elements of geometry, material choice, tool design and processing are all taken into consideration to optimise tooling, and ensure a repeatable manufacturing process.

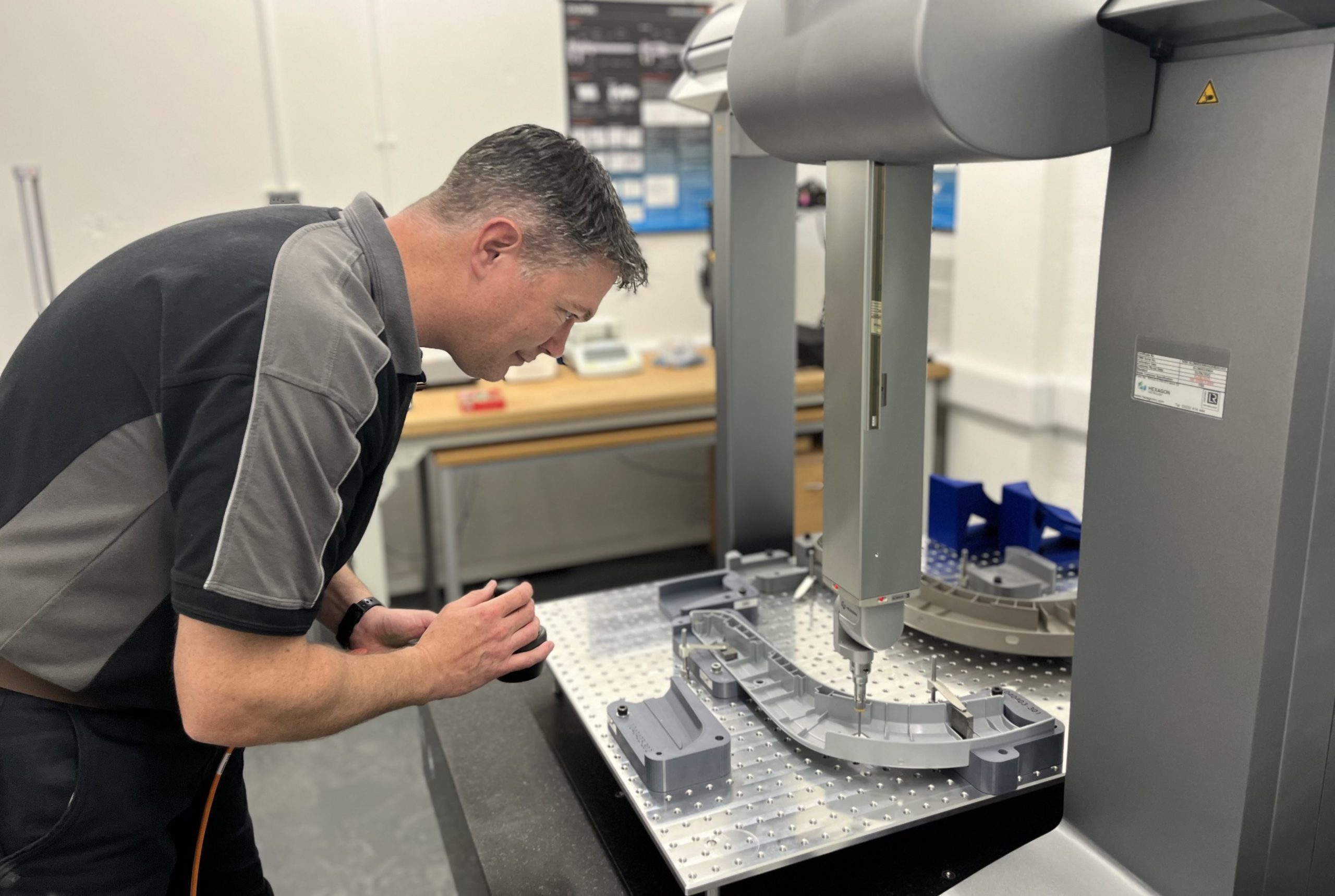

New Product Introduction

From simple visual confirmation and sample approval sign off, to full production part approval, we incorporate new products into our quality management system with First Article Inspection (FAI).

Production

Flexible volume, 24 hour continuous production of structural, flame retardant, lubricated, conductive and coloured engineering thermoplastics with value added through secondary operations and assembly build.

Aftermarket

We support the operational complexity that servicing aftermarket demand can present. Our goal is to ensure quality and continuity of supply throughout product whole life management.

2024 Statistics:

Parts

Delivery

Quality

“It never fails to delight me recognising IPC parts when travelling. From the latch assembly, seat trims, armrests or endbays on an aircraft seat, it is amazing to think that these highly cosmetic and visual components, interacting with millions of passengers annually, were made by our brilliant team in Carrickfergus, Northern Ireland.”

Joanne Liddle

Managing Director, IPC Mouldings“In a lean culture with just in time delivery across a diverse component range, we expect consignments every week across our global sites. We have complete faith in IPC as a supplier – in all the years we have worked with them, there has never been a line stop. They have never let us down. We know they are mission focussed, and will do whatever needs to be done. It’s one less thing we have to worry about. IPC is, and continues to be, a gold standard supplier to our business.”

Global Aircraft Cabin Interiors Customer

What we stand for.

Injection Moulding is at the heart of what we do at IPC Mouldings. An SC21 Gold award-winning manufacturer of technical plastic components, we have perfected the services we provide to our global customer base over the years, combining our knowledge and expertise with high quality performance and service. With ambitious plans in place for the future, we are committed to continuous improvement and this will be achieved thanks to the incredible team of people we have built around us here at our facility in Carrickfergus, Northern Ireland. Find out more about our company in our corporate video.

News.

IPC Mouldings is proud to have recently received the Impact Award from Autism NI in recognition of our commitment to inclusion in …

At IPC Mouldings, we are committed to investing in our people. We design and manufacture mould tools and supply plastic injection moulded …

AEROSPACE supply chain partners IPC Mouldings and Bradfor Ltd have both been honoured for their commitment to the aerospace sector at the …

Northern Ireland Aerospace Companies Set to Showcase at Hamburg Expo Amidst Surge in Aircraft Orders

With recent figures from January indicating a remarkable 168% increase in aircraft orders compared to 2024, reaching a total of 91 orders, …