Capabilities

Our non-typical, injection moulding business model has you, our customer, at the heart of its approach. We are versatile – offering low volume, high variety, agile manufacturing, managing change, whilst balancing a build-to-print approach. We understand customers’ emerging and ever-changing needs. We add value with secondary operations to modify products, and manage supply chains and product through mould evolution, product testing, certification and assembly. Our high degree of customer focus also extends to aftermarket and product life cycle management.

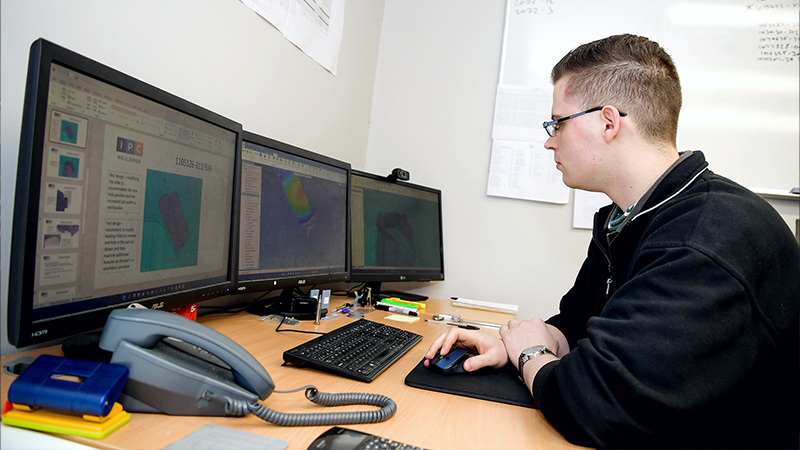

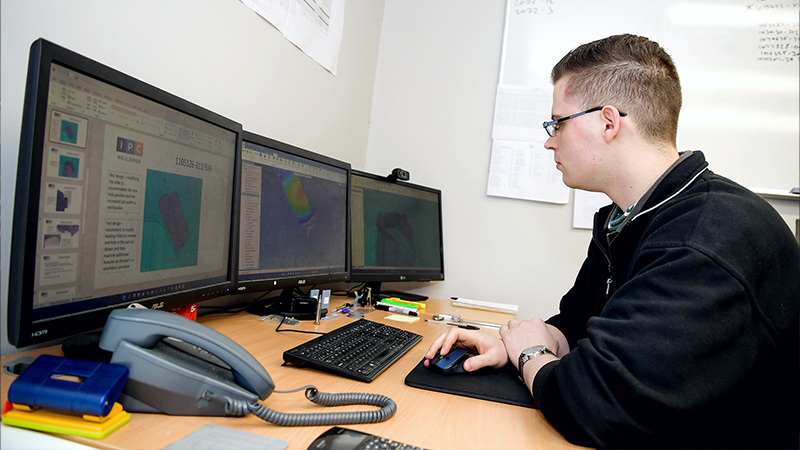

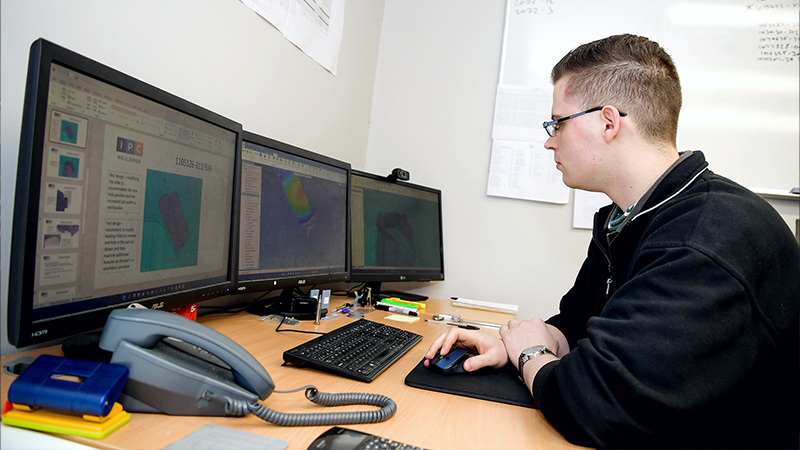

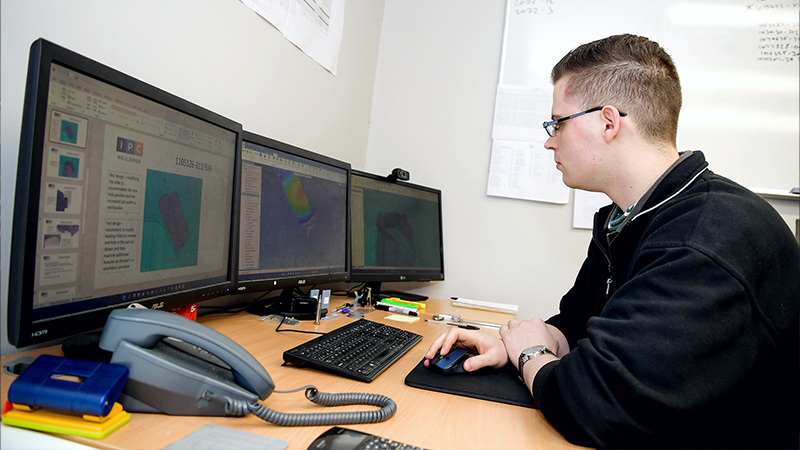

Design For Manufacture

Design For Manufacture.

Design For Manufacture

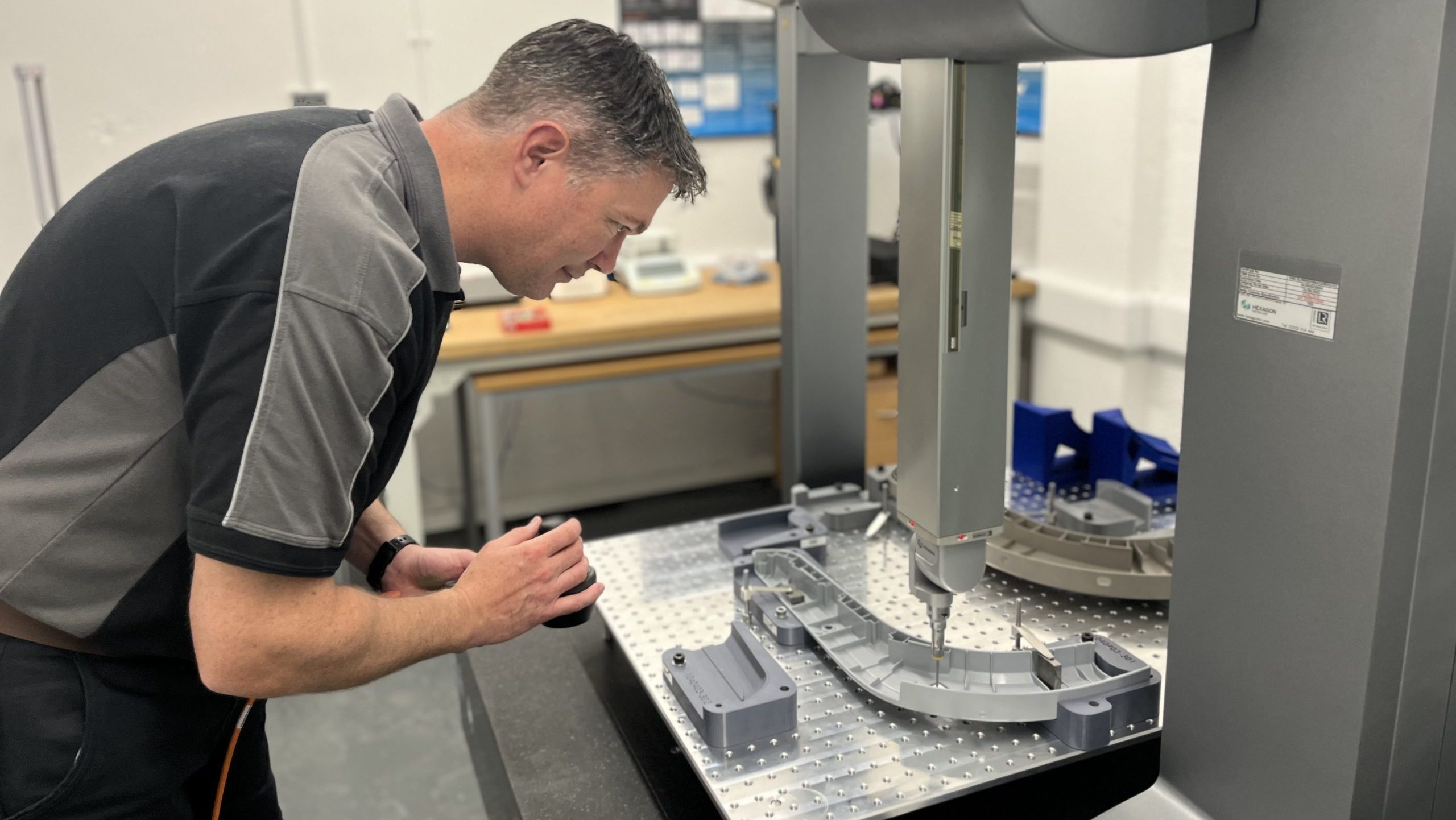

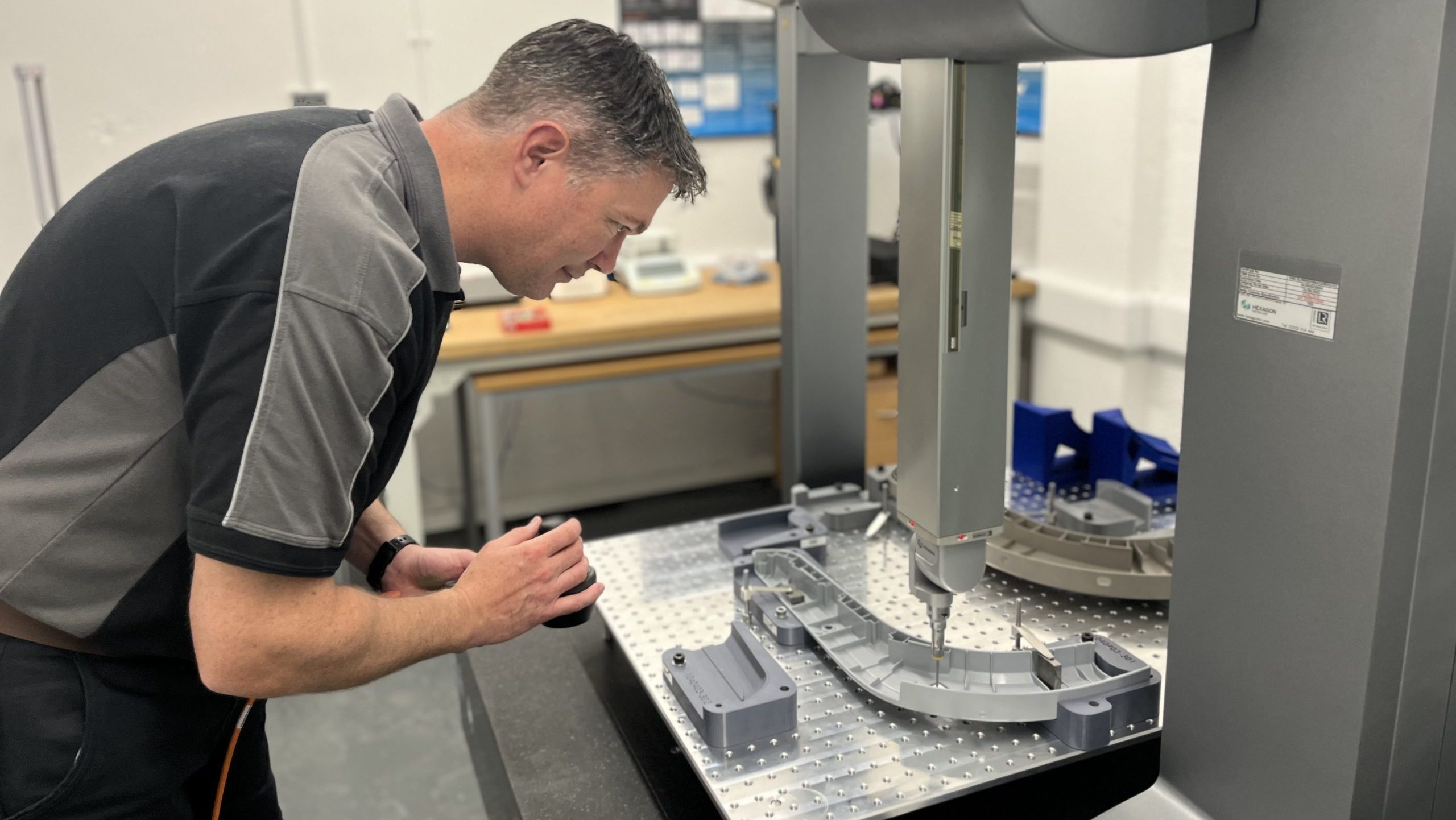

Mould Tools

Our customers can have absolute confidence that their mould tools will be accessible and ready for use as soon as they are required.

Mould Tools.

Mould Tools

Our customers can have absolute confidence that their mould tools will be accessible and ready for use as soon as they are required.

New Product Introduction

Once the above processes have been completed, we move on to the production stage.

New Product Introduction.

New Product Introduction

Once the above processes have been completed, we move on to the production stage.

Injection Moulding

Our company has extensive experience in the processing of structural, flame retardant, lubricated, conductive and coloured engineering thermoplastics and specific resins.

Injection Moulding.

Injection Moulding

Our company has extensive experience in the processing of structural, flame retardant, lubricated, conductive and coloured engineering thermoplastics and specific resins.

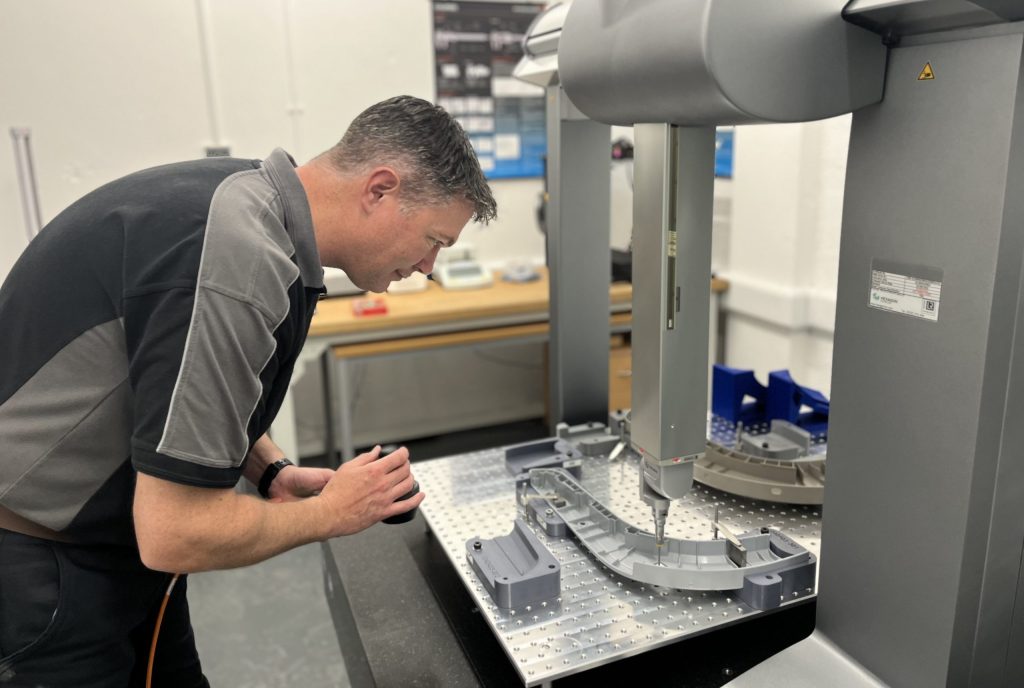

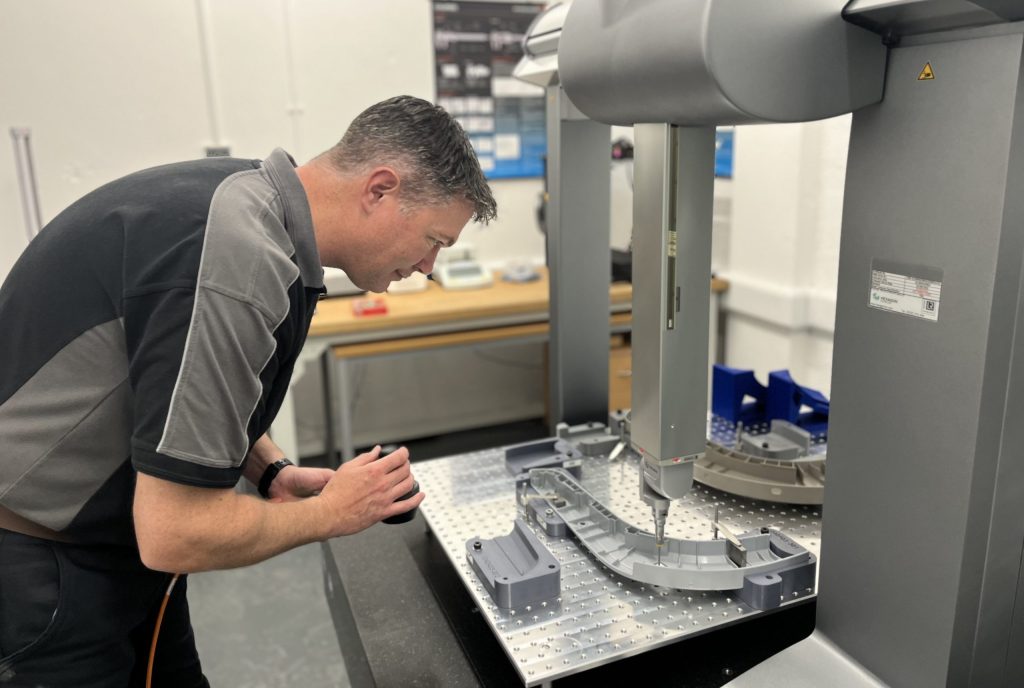

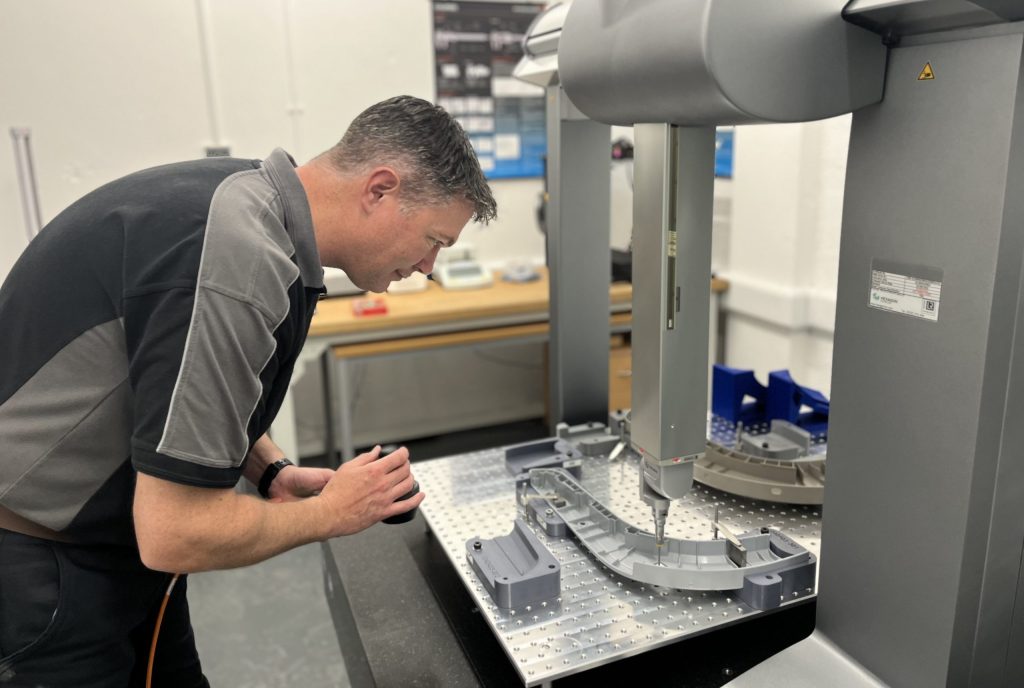

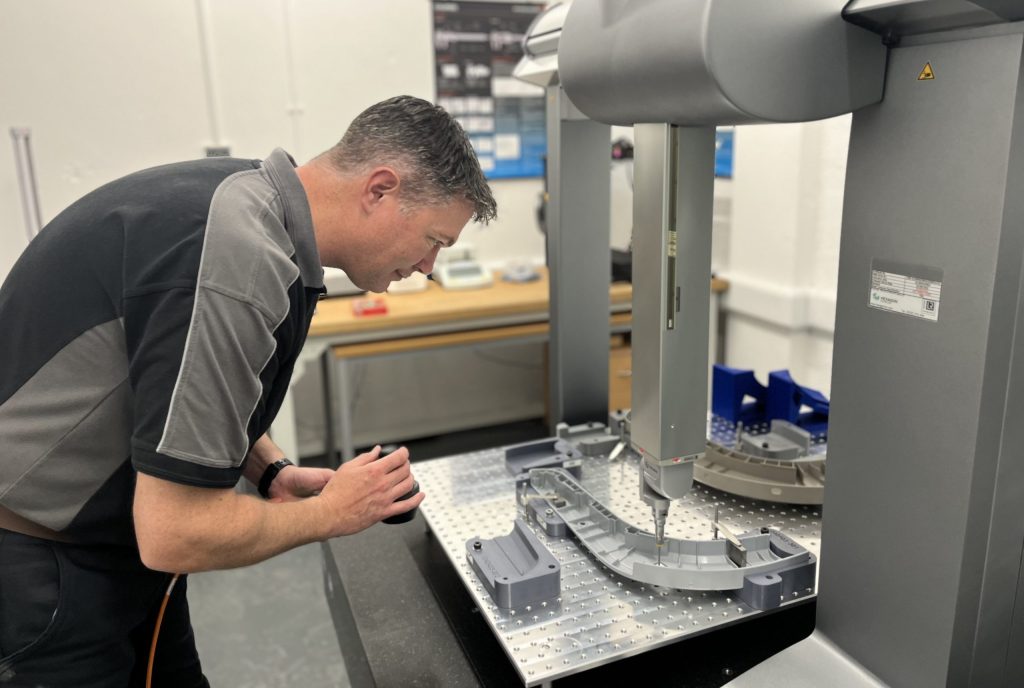

CNC Machining

We machine components in most polymers and metals. Our speciality lies in machining mixed volume bespoke components, and we can CNC machine a wide variety of materials. More than manufacturing as a service, our CNC secondary processes add value by machining multiple variants from a single moulded part, customised to meet requirement and reducing the need for additional tooling.

CNC Machining.

CNC Machining

We machine components in most polymers and metals. Our speciality lies in machining mixed volume bespoke components, and we can CNC machine a wide variety of materials. More than manufacturing as a service, our CNC secondary processes add value by machining multiple variants from a single moulded part, customised to meet requirement and reducing the need for additional tooling.

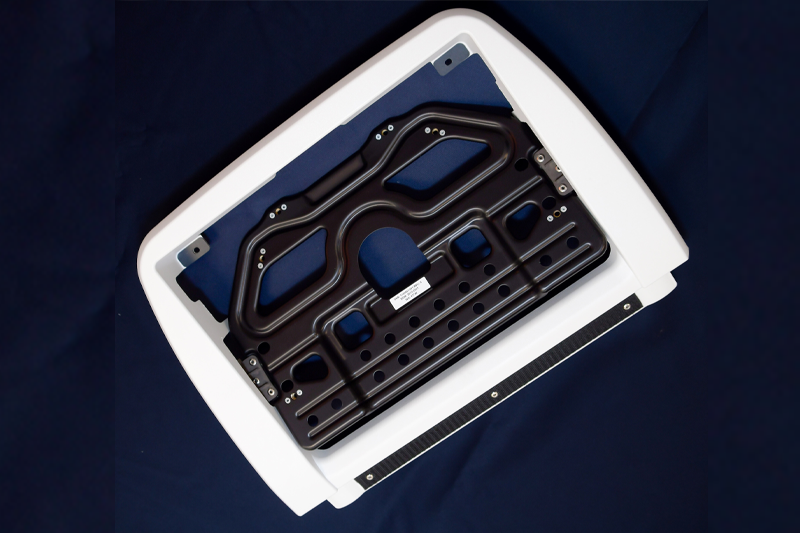

Assembly

Our team will take you through the entire process, offering complete guidance and bridging the gap from buyer to engineer. Simplifying the whole process and ensuring your whole team is well informed and ready for your project.

Assembly.

Assembly

Our team will take you through the entire process, offering complete guidance and bridging the gap from buyer to engineer. Simplifying the whole process and ensuring your whole team is well informed and ready for your project.

Design For Manufacture

Design For Manufacture.

Design For Manufacture

Mould Tools

Our customers can have absolute confidence that their mould tools will be accessible and ready for use as soon as they are required.

Mould Tools.

Mould Tools

Our customers can have absolute confidence that their mould tools will be accessible and ready for use as soon as they are required.

New Product Introduction

Once the above processes have been completed, we move on to the production stage.

New Product Introduction.

New Product Introduction

Once the above processes have been completed, we move on to the production stage.

Injection Moulding

Our company has extensive experience in the processing of structural, flame retardant, lubricated, conductive and coloured engineering thermoplastics and specific resins.

Injection Moulding.

Injection Moulding

Our company has extensive experience in the processing of structural, flame retardant, lubricated, conductive and coloured engineering thermoplastics and specific resins.

CNC Machining

We machine components in most polymers and metals. Our speciality lies in machining mixed volume bespoke components, and we can CNC machine a wide variety of materials. More than manufacturing as a service, our CNC secondary processes add value by machining multiple variants from a single moulded part, customised to meet requirement and reducing the need for additional tooling.

CNC Machining.

CNC Machining

We machine components in most polymers and metals. Our speciality lies in machining mixed volume bespoke components, and we can CNC machine a wide variety of materials. More than manufacturing as a service, our CNC secondary processes add value by machining multiple variants from a single moulded part, customised to meet requirement and reducing the need for additional tooling.

Assembly

Our team will take you through the entire process, offering complete guidance and bridging the gap from buyer to engineer. Simplifying the whole process and ensuring your whole team is well informed and ready for your project.

Assembly.

Assembly

Our team will take you through the entire process, offering complete guidance and bridging the gap from buyer to engineer. Simplifying the whole process and ensuring your whole team is well informed and ready for your project.

We are constantly evolving our offering to customers and growing with investment to match. We are small enough to be agile, and mature enough to align to corporate needs, with a diverse range of capability in product size and volume. Through innovation, we have the ability to anticipate our customers’ needs supported by a wide variety of value-add services that include assemblies, engineering change process, continuous improvement and re-shoring